LANCO secures a multi-million-dollar order in the Industrial sector.

Westbrook, Maine, USA – Lanco Integrated (“Lanco”) announced today that it has secured an order for a follow-on next Gen automated assembly and test production line from a world-leading metal processing and plasma cutting manufacturing company.

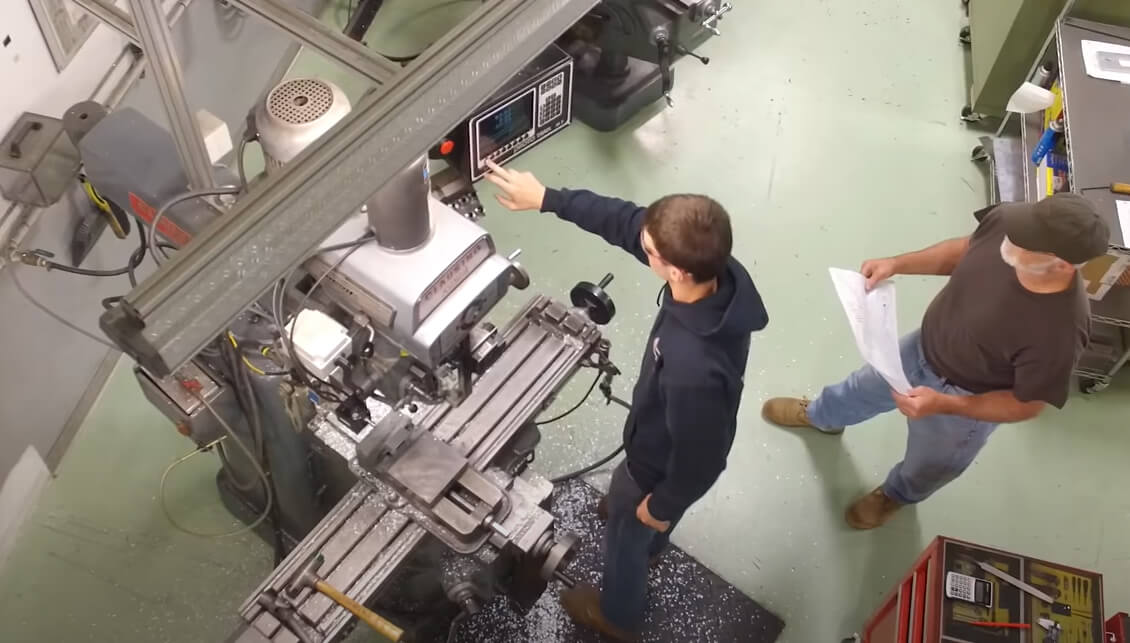

This project includes many serial assembly and in-line test stations for a fully automated production system with tray-feed, high precision pick-and-place, rotate, positioning, press, insert, leak-test, data collection/management/analytics tools, software technology, and Lanco’s own reliable power-and-free linear palletized transport system to ensure highest and most consistent performance.

“We are very excited to be selected again as the partner of choice by our customer for this project. Lanco’s integration solutions, precision engineering, and deep knowledge of automated process control technology for these applications result from years of subject matter expertise in providing the confidence and reliable performance expected and required by our customers” – Barry Rahimian, Global VP of Sales and Business Development.

Lanco Integrated, an ESOP company and an industry-leading precision engineering and automation technologies and solutions provider to the global market, with over 8000 systems installed in more than 30 countries, serves life sciences, automotive, consumer products, and industrial products and commercial sectors.

Extended capabilities include:

◾ Early-stage DFA (Design for Automation) and DFM-readiness consulting services

◾ Comprehensive design and systems integration

◾ Post-install service offerings (S3®-Service, Support, and Spares)

◾ Performance Improvement Solutions

MEDIA: Sarah Jennings ([email protected])