We develop innovative automated assembly and test solutions tailored to your exact specifications to maximize your assembly production, lower costs, keep you competitive and ensure your systems reach the highest Overall Equipment Effectiveness (OEE).

Manual, Semi-Automatic and Fully Automatic

Manual, Semi-Automatic and Fully Automatic

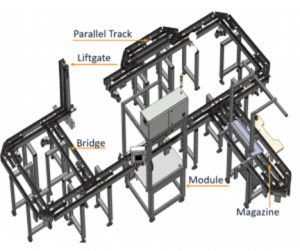

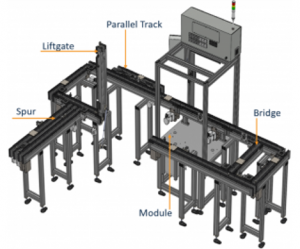

Support your current production demands while planning for future expansions with our flexible automation platforms. Lanco’s modular design allows your systems to grow with your increasing needs.

Learn MorePallet Transfer Systems

Pallet Transfer Systems

Safely and quickly transfer components for assembly and test with precision on Lanco’s HFL 2002-S or the MPS 120 Mini-pallet system. Each designed to optimize productivity and efficiency.

Learn MoreRobot Cells

Robot Cells

Designed to improve speed, efficiency and quality for repeatable tasks.

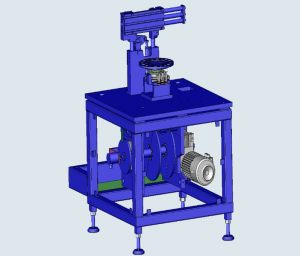

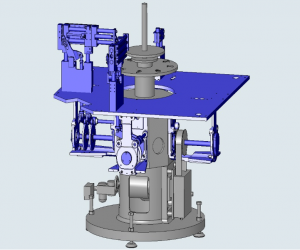

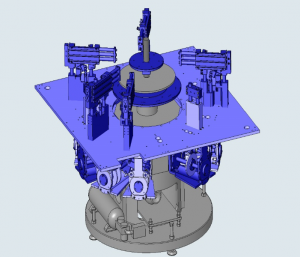

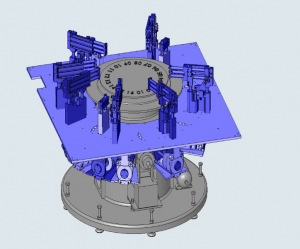

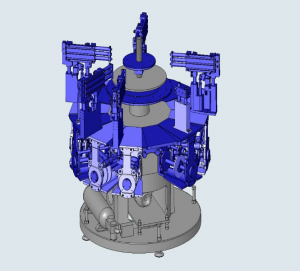

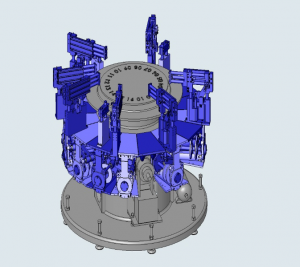

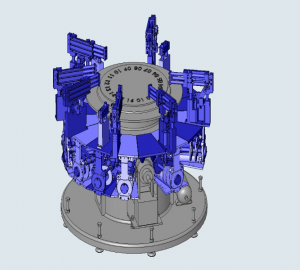

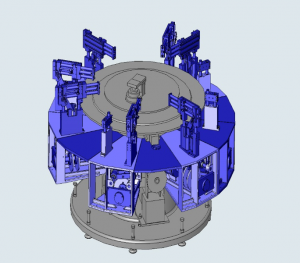

Learn MoreRotary Dials

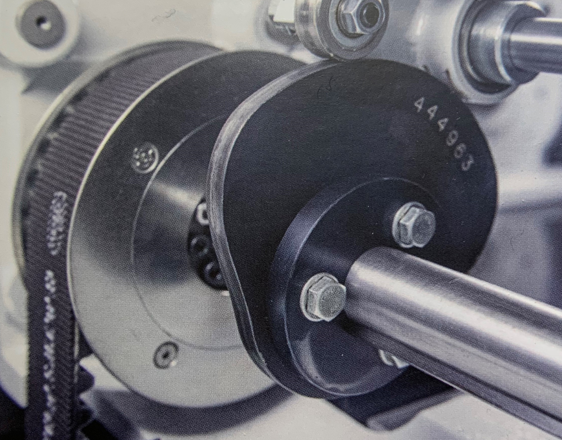

Rotary Dials

Achieve precise and reliable automation with compact rotary dial platforms specifically designed to minimize floor space requirements.

Learn More

Your Needs Define the Technology

Custom Global Automation and Assembly Solutions

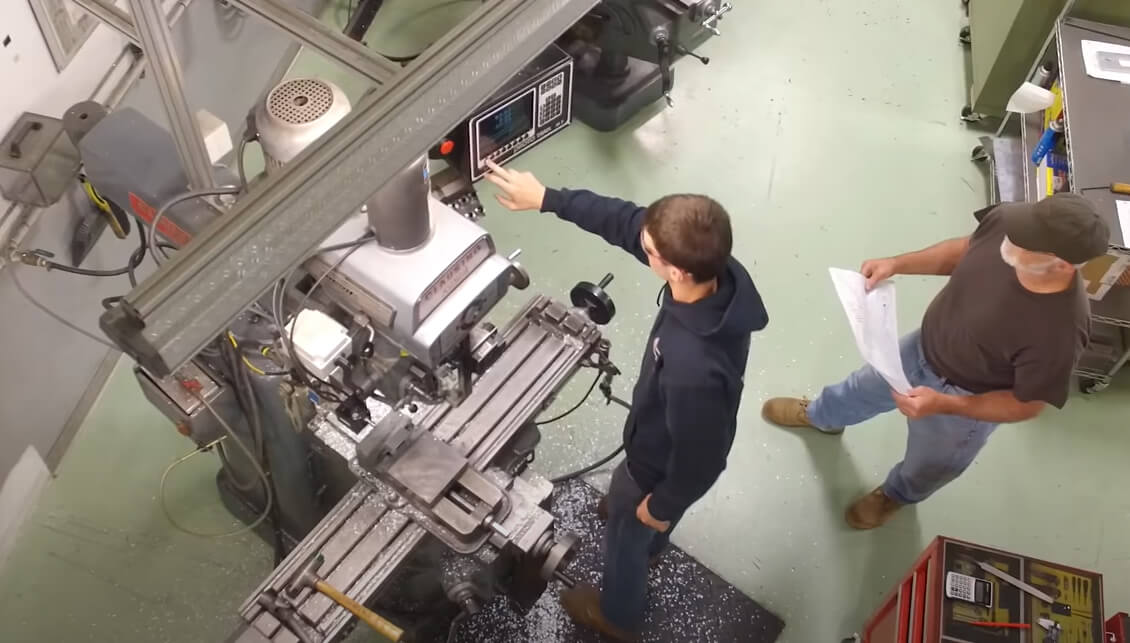

Your goal is simple: achieve the highest possible output rates at the highest levels of efficiency. Our goal? Determine the ideal match between your needs and our automation capabilities to help you meet your production goals. Our proven process focuses on a collaborative approach; together with your product design and manufacturing experts we’ll integrate technologies that have the biggest impact on your success.

Leaders from your organization directly work with our experienced automation engineers who specialize in the design and manufacturing of automated systems. Our experts understand each manufacturing site has specific needs for efficient automation and we analyze everything from your current assembly process to your output goals to develop your cohesive automated system.

Your Partner in Automation Technology Innovation

World-Class Customer Service and Automation Technology

As an automation technology company, increasing your production efficiency isn’t our only goal. We strive to exceed your expectations at every stage in the process and be a valued partner as you grow and expand. Our Total Service Solution outlines the engagement and collaboration you can expect through the entire development process. From our first discussion to post system installation services, we maintain a transparent, open and easy-to-access team structure so you’re familiar with every module, station, and feature of your system.

Lanco offers a worldwide design, sales, manufacturing, and service network committed to ensuring you have local access to our wide range of systems and machine expertise. Our global presence and partnerships have produced more than 8,000 systems with relationships spanning over 30 years.

Products Available for Purchase