A Philosophy Built Around Your Success

The Lanco Integrated Total Service Solution

Stage 1: Sales Experience

Your initial conversation with us is more than just a sales discussion. It’s the beginning of a partnership. We bring more than 60 years combined industry experience to begin a collaborative process to achieve the best product for you. By combining our automated assembly industry expertise with your production goals, we optimize automated manufacturing solutions for your specific assembly process and output goals. If you have a process you want to test, we can create the prototype to evaluate the potential of any designed system.

Through this first stage, we solidify the foundation for a successful partnership. In fact, our track record includes many partnerships spanning more than 30 years. That’s a partner you can count on.

Stage 2: Contract Award

Our proactive approach makes it easy to work together. We engage our leadership team and your key stakeholders from the beginning to avoid hindrances to progress or any possible barriers to our success together. With our collaborative approach, leaders from your organization and ours work together to define the path to success and reach an agreement.

Avoid guesswork and surprises as we carefully review your contract and discuss terms and conditions on-site or virtually. Ensure everyone is on the same track as we clarify the project requirements, timeline expectations, responsibilities and accountabilities. Move forward in your project knowing exactly what to expect.

Stage 3: Customer Kick Off

Just like your automated machines will work together as a harmonious cohesive unit, developing your system requires people working together and open lines of communication. We’ve perfected a highly collaborative process where your product expertise and knowledge is merged with our engineering and design skills. We involve key process owners from our organization together with yours to review even the smallest project details and requirements. As we move forward you will always have access to critical project information, and our project management, engineering and controls teams. We ensure everyone has a clear understanding of expectations and the project timeline.

Our commitment to collaboration paves the most direct way to a clear path to success. Our weekly progress report meetings and project action lists ensure your project stays on track. Up-to-date statuses mean you keep your future production forecasts accurate and any project block is resolved as quickly as possible.

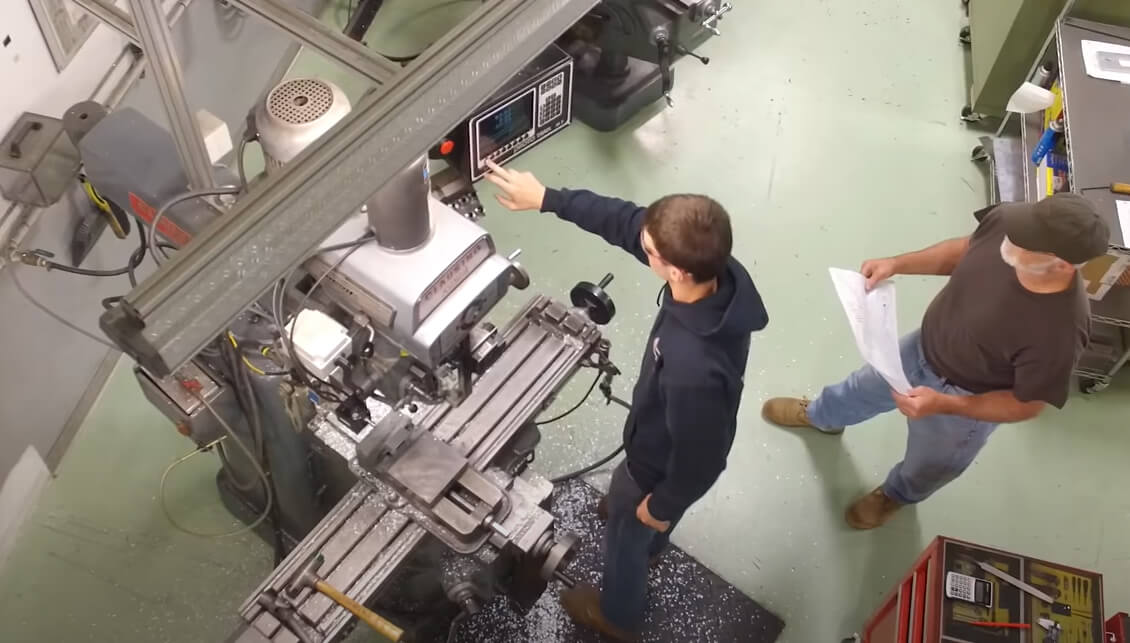

Stage 4: Customer Design Review

Before our experts bring your vision to fruition, our design review process verifies we created the best automation solution for your needs. This is the culmination of all mini review sessions to this point. Together we take an in-depth look at how each station operates and how our designs will set the stage for your success.

We encourage your active feedback throughout the process to guarantee your custom system meets your manufacturing needs and exceeds your expectations. Confident that we’ve captured all your needs and expectations we’ll welcome your feedback and gain mutual commitment that we’re on the path to success. Once you approve the design, we initiate our production processes that have led to more than 8,000 successful installations worldwide. We encourage you to take advantage of our fully open-door policy to see our progress firsthand.

Stage 5: FAT

It’s time to see what we achieved together. We invite you and your team to visit us on-site or virtually to take part in the FAT. Take advantage of hands-on training with the team of experts who built your system. Your machine commissioning includes performance testing to ensure the design benchmark metrics are achieved.

Our documented line data captures availability, performance and quality to ensure your OEE aligns with your equipment acceptance runoff criteria. Once we complete all training and testing, we’ll review with a closeout meeting to assist you in preparing for a successful launch at your facility.

Stage 6: SAT

See your ROI in real time as our team of experts installs and commissions your line. They complete additional performance testing, ensuring all equipment is ready for production. Our partnership with you continues as our experts spend time with your team to become comfortable with the operation and maintenance of your assembly system.

Stage 7: OEE Optimization Services

Know that your manual, semi-automated or fully automated assembly system will serve your company for years with the support of our dedicated service organization. Take advantage of training, remote service capabilities, annual contract offerings and more to maintain your system’s exceptional performance.

Experiencing dynamic growth? Need more from the Lanco Integrated assembly system already powering your efficiency? No problem. We design our systems to grow and adapt with your production needs. Talk to our automation solutions experts about the latest innovative technologies. We’re always available to help you identify opportunities to use assembly automation to fuel your growth. That’s our day one commitment to you as your partner.

Spare Parts Request

Avoid disruptions to your daily operations. Maintain optimal OEE with easy access to spare parts for your planned maintenance.

Learn MoreService Request

Request maintenance today to preserve the optimal performance of your system. Get the efficient service you need from the qualified experts you trust.

Learn More“The Lanco team was highly motivated and worked long hours to build the machine, deliver, install and qualify for production. The team has continued to support the project and we are working on further automation to reduce the headcount necessary to make rate.”

Steve, Director of Manufacturing Engineering - Leading Medical Device Manufacturer