Retool, Rebuild or Start Over?

Retool, Rebuild or Start Over?

In the right application, manufacturers can reuse some or all of existing assembly systems for new projects.

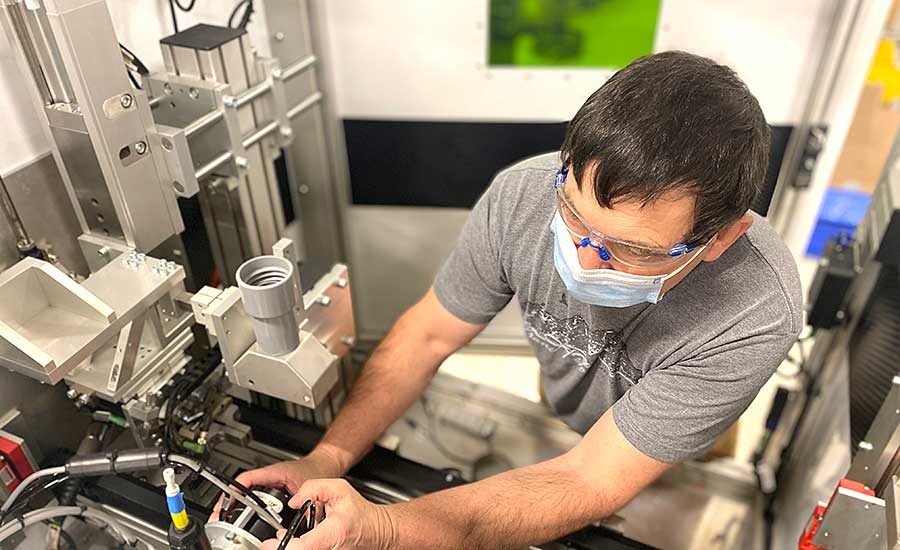

Manufacturing technician Christopher Lord adjusts a mechanism inside an automated assembly system. Photo courtesy Lanco Integrated

In that light, it may seem counterintuitive to expect a multistation automated assembly system to last for a decade or more, but there are examples out there. In 1990, Lanco Integrated built a machine to assemble compacts for a cosmetics company. That machine is still running today. And why not? While cosmetics colors might change with fashion trends, the basic form factor of the compact itself has not. Thus, with proper maintenance and little or no changes in tooling, the machine has been able to churn out product for years.

“That customer has made an absolute fortune off of our machine,” boasts Tim Neale, global account manager at Lanco.

Retooling and reusing an entire assembly system is a different proposition. In some cases, it could hamper the integrator’s ability to design the most efficient and effective system. But, it can be done.

“We have retooled existing systems to make a similar product or a family of similar products,” says Neale, adding that “similar product” is the operative phrase.

“You can’t assemble a medical device on a system that was originally designed to produce an automotive part,” he notes.

In addition, says Neale, deciding to retool an existing system or start from scratch is like deciding whether to a buy a used car or a new one. Sure, an older car might cost less, but a new vehicle will have all the latest technology, like air bags and driver assist systems.

In February, Lanco shipped out a retooled assembly system for a medical device manufacturer. That system featured new servo-driven electric actuators and a state-of-the-art laser welding system.

“It was a perfect application for retooling,” says Neale. “The customer saved money, and it got a machine equipped with the latest technology.”

Asynchronous systems built around pallet-transfer conveyors are easier to retool and reconfigure than synchronous systems built around linear or rotary indexers.