- Medical Device

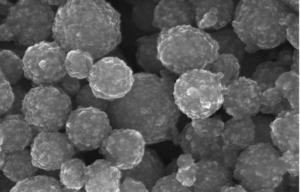

Barcoded Magnetic Beads

Lanco partnered with the customer to design and build a repeatable and automated solution for a very critical process. This has traditionally been a manual process. A vial of the bioassay solution is the final product. This product consists of an accurate distribution and agitation of a solution

Read More... - Medical Device

Winding Case Study

Lanco Integrated developed A fully automated process to produce a Suture and Needle assembly and Package. The initial processes developed by Lanco Integrated required a system to produce a complete Surgical Needle and Suture every 4.0 seconds. Sequences included automated feeding of Packaging

Read More... - Medical Device

Technology – Lab System

The customer partnered with Lanco to scale an existing manufacturing system, taking it from full scale production size to a smaller scale, low cost lab size. The quality and performance of this new design needed to leverage and function as its full-size self, but provide a product that met budget,

Read More... - Automotive

Regenerative Brake Module Case Study

Lanco Integrated developed an automated process to assemble the electronics control module for a “brake-by-wire system “, allowing for regenerative braking in electric or hybrid-electric vehicles. The modules were required every 15 seconds and the process consisted of: Dual manual loading stations

Read More... - Feeding Systems

Feeding Systems

Lanco had the task of providing 10 fastening clips for all 4 doors on the car (one model series) as quickly as possible using a feeding device. The customer’s robot picked up the 10 clips and mounted them accordingly on the inside of the doors. Lanco designed and produced 4 feeding

Read More... - Electronics

Electronic Component Processing

Lanco Integrated developed a fully automated system to produce the front panel of a residential electric meter at a rate of 700 parts per hour. Sequences included robotic unloading of plastic Housings and LCD’s from trays, removal of protective film from LCD, feeding and placing of conductive

Read More... - Sanitizer Dispensing

Consumer Soap Dispenser Pump

Lanco Integrated developed a fully automated high-speed assembly system to produce six different variants of a soap dispenser pump at a rate of 3600 parts per hour. This was the first of ten machines designed and commissioned for this customer during the last 11

Read More... - Commercial Irrigation

Case Study for Water Irrigation Drippers

Lanco developed a fully automated assembly system to produce large volume water irrigation dripper

Read More... - Electronics

Case Study for High-Precision Mechanical Switches

Lanco Integrated developed a fully automated assembly line to produce switch assemblies. The assembly line built on a cam platform operates 2-up for assembly and testing with a gross output of 90 parts/minute. The main processes are: Delicate high-speed parts feeding Metal and plastic part

Read More... - Automotive

Automotive Brake Module Assembly

Lanco Integrated developed an automated system to produce a brake module assembly at a rate of 257 parts per hour. Sequences included robotic dispensing of silicone, cutting, forming & welding of terminals to coil, robotic dispensing of potting material, UV curing, robotic dispensing of gasket

Read More... - Medical Device

Cam Driven Case Study

Lanco Integrated delivered an assembly machine with high volume part output for capped vials with different diameters and lengths. The solution integrated a fully mechanical driven base machine with automated part feeding. Capacity of the machine calculates by a 4-track design, 35 cycles in a

Read More...